How can Generative AI Transform Manufacturing in 2024 and Beyond?

As we enter 2024, the convergence of cutting-edge technologies is reshaping the manufacturing landscape, with Generative AI emerging as a transformative force. Generative AI, a subset of AI that excels in creative problem-solving and content generation, holds immense potential to revolutionize manufacturing processes.

In this exploration, we dive into how Generative AI is poised to transform manufacturing in 2024 and beyond, uncovering its applications, benefits, and the unprecedented possibilities it brings to the forefront of the manufacturing industry.

From design innovation to production optimization, the integration of Generative AI in manufacturing promises a paradigm shift, redefining how products are conceived, developed, and brought to fruition in the evolving industrial landscape.

Current Landscape of Manufacturing

The manufacturing industry is undergoing a transformative phase marked by a blend of challenges, technological advancements, and the pursuit of operational excellence. Here, the current manufacturing landscape focuses on the challenges faced by the industry, the existing technologies driving automation, and the potential for improvement through the integration of advanced technologies like Generative AI.

A. Challenges Faced by the Manufacturing Industry:

- Supply Chain Disruptions: The manufacturing sector grapples with global supply chain disruptions, impacting the timely procurement of raw materials and components. External factors such as geopolitical events, natural disasters, and the ongoing global pandemic have highlighted the vulnerability of manufacturing supply chains.

- Operational Inefficiencies: Many manufacturing processes still need to improve efficiency from manual workflows, legacy systems, and suboptimal production planning. Streamlining operations to reduce waste, enhance productivity, and improve overall efficiency remains a priority for manufacturers.

- Skill Shortages and Workforce Challenges: The evolving nature of manufacturing demands a skilled workforce capable of handling advanced technologies. However, the industry needs help attracting and retaining skilled talent, hindering the seamless integration of innovative technologies into manufacturing processes.

B. Overview of Existing Technologies and Automation in Manufacturing:

- Internet of Things (IoT) and Smart Manufacturing: IoT has become integral to intelligent manufacturing, enabling the connectivity of devices and machinery. Sensors and data analytics provide real-time insights into production processes, facilitating predictive maintenance, quality control, and overall optimization of manufacturing operations.

- Robotics and Automation: Robotics and automation technologies continue to evolve, reducing human intervention in repetitive and hazardous tasks. Robotic arms, automated guided vehicles (AGVs), and collaborative robots (cobots) are increasingly employed to enhance manufacturing precision, speed, and safety.

- 3D Printing and Additive Manufacturing: Additive manufacturing technologies, including 3D printing, are revolutionizing prototyping and production. These techniques offer flexibility in design, reduce material waste, and enable the creation of complex geometries, contributing to advancements in rapid prototyping and customized production.

C. Potential Areas for Improvement Using Generative AI in Manufacturing:

- Design Optimization: Generative AI in manufacturing can revolutionize the design process by automatically generating and optimizing designs based on specified parameters. This leads to more efficient and resource-friendly product designs, accelerating innovation and reducing time-to-market.

- Production Planning and Scheduling: Generative AI can optimize production planning by analyzing historical data, demand forecasts, and supply chain dynamics. This results in more accurate and adaptive production schedules, minimizing idle time and optimizing resource utilization.

- Predictive Maintenance: Integrating Generative AI into manufacturing machinery allows for predictive maintenance models. By analyzing real-time data from sensors, the AI can predict equipment failures, enabling proactive maintenance to avoid unplanned downtime and extend the lifespan of machinery.

- Supply Chain Optimization: Generative AI algorithms can enhance supply chain management by optimizing inventory levels, predicting demand fluctuations, and identifying alternative sourcing strategies. And contributes to more resilient and responsive supply chains in the face of disruptions.

Real-world Examples

Generative AI’s transformative power is no longer mere speculation. Across diverse industries, manufacturers are reaping the rewards of this potent technology, pushing the boundaries of efficiency, innovation, and sustainability. Let’s delve into a few inspiring case studies:

1. Nike and Generative Design: The sportswear giant partnered with Autodesk to use Generative AI for footwear design. AI algorithms analyzed vast datasets on athlete performance, material properties, and manufacturing constraints, then churned out hundreds of innovative shoe designs. Result? 13% lighter, 4% stronger midsoles in record time, proving Generative AI’s ability to unlock game-changing product optimization.

2. Siemens Energy and Supply Chain Resilience: The energy giant implemented AI to predict potential disruptions in its global supply chain. The AI proactively recommended alternative suppliers and adjusted production schedules by analyzing historical data and real-time market trends. This agility enabled Siemens to weather a significant raw material shortage, minimize downtime, and maintain smooth operations.

3. Unilever and Sustainable Packaging: The consumer goods giant used Generative AI to generate sustainable packaging designs for personal care products. AI algorithms explored millions of possibilities, considering material strength, biodegradability, and consumer preferences. The result? 10% reduction in plastic usage without compromising product integrity, showcasing Generative AI’s potential for environmental impact reduction.

4. Airbus and Generative Design for Aircraft Parts: The aerospace giant adopted Generative AI to design lighter, more robust aircraft components. AI-optimized internal structures, minimizing material usage while exceeding performance requirements. This resulted in weight reductions of up to 50% in some parts, leading to fuel savings and improved aircraft efficiency.

5. Johnson & Johnson and Personalized Medical Devices: The healthcare company explored Generative AI to design custom-fitting medical devices for individual patients. By analyzing scans and medical data, AI-generated personalized designs for prosthetics and dental implants ensure improved comfort, functionality, and patient outcomes.

These diverse examples showcase Generative AI’s versatility and impact across manufacturing sectors. The benefits are tangible and transformative, from optimized designs and streamlined processes to resilient supply chains and sustainable packaging.

The message is clear: Generative AI is not just a buzzword; it’s a catalyst for real-world change. By embracing its potential and navigating the challenges with a focused vision, manufacturers can unlock a future where innovation thrives, efficiency reigns, and sustainability becomes the cornerstone of a reimagined manufacturing landscape.

So, take inspiration from these real-world stories and ignite your own Generative AI-powered success story. The future of manufacturing awaits, crafted with a blend of human ingenuity and artificial intelligence.

Future Trends and Innovations

The year is 2024, but Generative AI’s journey in manufacturing has just begun. As we peer into the future, the horizon shimmers with exciting trends and innovations, promising to revolutionize the very fabric of production further.

A. Predictions for Generative AI’s Ascendance:

- Beyond Optimization to Creation: The future goes beyond tweaking existing designs. Generative AI will conceptualize entirely new products and functionalities, catering to unmet needs and pushing the possible boundaries. Imagine AI-designed biomaterials for revolutionary prosthetics or self-repairing structures inspired by nature.

- Hyper-personalization Reigns: Mass customization will reach its pinnacle. Generative AI will personalize products in appearance, performance, and adaptability, tailoring them to individual preferences and real-time usage patterns. Picture adaptive shoes that adjust to your unique gait or clothing that changes color based on your mood.

- Closed-Loop Manufacturing: Waste becomes a distant memory. Generative AI will optimize resource utilization within a circular economy, repurposing waste materials and designing products with disassembly and recycling in mind. Imagine factories resembling self-sustaining ecosystems, where production fuels creation and vice versa.

B. Emerging Technologies and AI’s Symphony:

- Edge Computing and Decentralized Intelligence: Decision-making won’t be confined to centralized servers. Generative AI will integrate with edge computing, empowering localized intelligence on the factory floor. Imagine AI algorithms in intelligent machines making real-time adjustments based on sensor data and production fluctuations.

- Digital Twins and Augmented Reality: The lines between physical and digital blur. Generative AI will fuel the evolution of digital twins, creating highly accurate simulations of production lines and products. Imagine testing thousands of design iterations in a virtual world before committing to physical production.

- Human-AI Collaboration: The future isn’t about machines replacing humans. Instead, Generative AI will become an influential collaborator, amplifying human creativity and problem-solving abilities. Imagine designers and engineers co-creating with AI, leveraging its vast knowledge and computational power to unlock groundbreaking solutions.

C. Navigating the Future with Vision and Adaptability:

As we embrace these trends, challenges will arise. Data security, ethical considerations, and the need for upskilling the workforce will require careful attention. But by navigating these challenges with vision and adaptability, we can ensure that Generative AI empowers a future of:

- Unprecedented Innovation: Products and processes will evolve unimaginably, fueled by boundless creativity and data-driven insights.

- Enhanced Efficiency and Sustainability: Factories will become havens of resource optimization and minimized environmental impact, guided by intelligent resource management and closed-loop processes.

- Resilient and Adaptive Production: Supply chains will adapt to disruptions in real time, and production lines will adjust to changing market demands, ensuring agility and responsiveness in a dynamic world.

Generative AI in manufacturing isn’t just a technological phenomenon; it’s a catalyst for a global transformation. By embracing its potential and navigating the challenges with open minds and collaborative spirit, we can orchestrate a symphony of innovation and efficiency, crafting a future where human ingenuity and artificial intelligence seamlessly blend to reshape the essence of how we make things.

Implementation Strategies: Bridging the Gap Between Generative AI and Your Factory Floor

The potential of Generative AI in manufacturing is undeniable, but translating that potential into reality requires a strategic approach. Here are some essential guidelines to guide your journey:

A. Charting Your Course: Generative AI Integration Roadmap:

- Identify Opportunities: Scrutinize your manufacturing processes and pinpoint areas where Generative AI can optimize design, improve efficiency, or personalize production. This could be product design, supply chain optimization, or predictive maintenance.

- Start Small, Scale Smart: Wait to overhaul your entire operation overnight. Begin with pilot projects in well-defined areas, allowing you to test the waters and gain valuable insights before scaling up.

- Data is King: Generative AI thrives on robust data sets. Ensure you have the data infrastructure and quality protocols to feed the AI engine with accurate and comprehensive information.

- Collaboration is Key: Partner with experienced AI developers and consultants who understand Generative AI technology and your specific manufacturing challenges. Their expertise can accelerate your implementation process and avoid costly pitfalls.

B. Upskilling Your Workforce: The Human-AI Symphony:

- Embrace Change: Upskill your workforce through training programs on Generative AI concepts, its impact on your specific operations, and how to collaborate effectively with this powerful technology.

- Bridge the Gap: Foster communication and collaboration between AI experts and your existing teams. Create shared learning spaces and encourage knowledge exchange to bridge the technical and operational divides.

- Empower Your People: Don’t view AI as replacing human workers. Instead, it highlights its potential to augment human capabilities, freeing employees from tedious tasks and empowering them to focus on higher-level problem-solving and creative innovation.

C. Building a Sustainable Foundation:

- Security and Ethics: Implement robust security measures to protect sensitive data and ensure ethical use of Generative AI throughout your operations. Align your practices with evolving AI regulations and industry best practices.

- Continuous Improvement: Embrace an iterative approach. Use feedback loops to constantly refine your Generative AI models and optimize their performance over time. Track progress and measure the impact of your AI initiatives to demonstrate their value to stakeholders.

- Investing in the Future: View Generative AI not as a one-time cost but as a long-term investment in your future success. Consider ongoing AI research and development partnerships or internal innovation hubs to stay ahead of the curve in this rapidly evolving field.

Conclusion

The transformative potential of Generative AI in manufacturing is poised to reshape the industry landscape in 2024 and beyond. Fusing advanced artificial intelligence capabilities with manufacturing processes opens unprecedented avenues for innovation, efficiency, and product development. Generative AI’s ability to autonomously generate designs, optimize workflows, and predict outcomes heralds a new era in manufacturing where creativity meets precision.

The application of Generative AI in manufacturing holds the promise of streamlining production cycles, reducing costs, and enhancing product quality. By leveraging Generative AI in Manufacturing, businesses can unlock novel design possibilities, accelerate prototyping, and adapt swiftly to market demands.

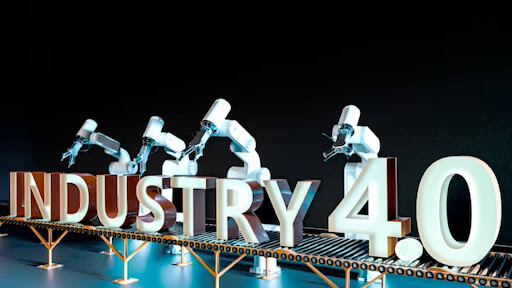

As we advance, the integration of Generative AI in Manufacturing will likely become a cornerstone of Industry 4.0, where intelligent factories leverage data-driven insights and autonomous decision-making to revolutionize the entire manufacturing ecosystem.

In summary, the transformative influence of Generative AI on manufacturing is a paradigm shift, offering a glimpse into a future where efficiency, sustainability, and innovation converge. By harnessing the power of Generative AI in Manufacturing, businesses can chart a course toward a more agile, intelligent, and responsive manufacturing landscape, setting the stage for a future where intelligent machines and human ingenuity coalesce for unprecedented success.

Generative AI Services from [x]cube LABS

[x]cube has been AI-native from the beginning, and we’ve been working through various versions of AI tech for over a decade. For example, we’ve been working with the developer interface of Bert and GPT even before the public release of ChatGPT.

[x]cube LABS offers key Gen AI services such as building custom generative AI tools, the implementation of neural search, fine-tuned domain LLMs, generative AI for creative design, data augmentation, natural language processing services, tutor frameworks to automate organizational learning and development initiatives, and more. Get in touch with us to know more!

![Blog-[x]cube LABS](https://d6fiz9tmzg8gn.cloudfront.net/wp-content/uploads/2016/06/blog_banner.jpg)